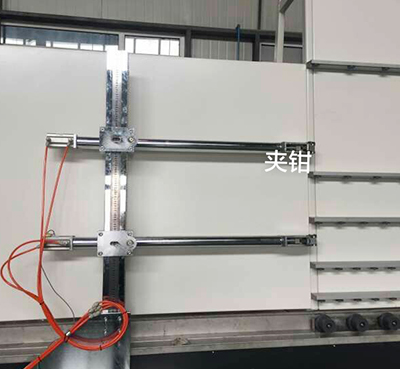

Vertical CNC glass drilling and milling machine is the perfect equipment for man-machine automation. It integrates the processing technology of ordinary vertical drilling machine drilling, water-jet milling and CNC machining center edging, and combines CNC numerical control technology. Achieve processing accuracy and stable quality. All procedures are installed at one time, and processing is completed at one time according to the optimized and set process route by default, which improves work efficiency. This type of processing production line program is upgraded to the field of artificial intelligence automation. It can process architectural glass such as frameless doors, bathroom doors, glass curtain walls, glass guardrails, staircase glass, etc. It is the first choice for CNC processing equipment in this field.

1. GC-LDM adopts the advanced Japanese Mitsubishi CNC system to realize the continuous contour trajectory control of each feed axis, precise high-speed positioning, and multi-task concurrent operation. So as to meet the urgent needs of customers for processing accuracy, processing quality and processing efficiency.

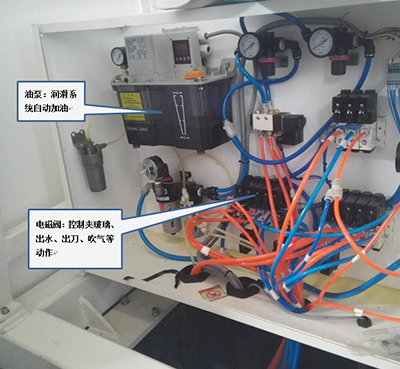

2. Low-voltage electrical appliances adopt French Schneider, with high reliability.

3. The software Easy CAM is developed by a team of professional software and process engineers. The library comes with 40 commonly used graphics and is based on size-driven parametric drawing. You only need to enter the necessary size and position to automatically generate the best The processing process path. EasyCAM supports office drawing, on-site call drawing processing and other functions.

4. The main machine structure of this machine tool uses finite element analysis software. After many iterations of analysis and structural optimization, the natural frequency of the main machine avoids the processing frequency range, avoids resonance, and obtains a stable accuracy guarantee within the effective working range.

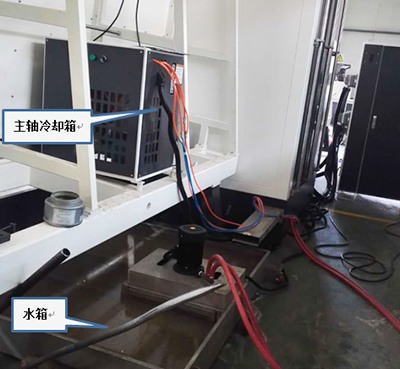

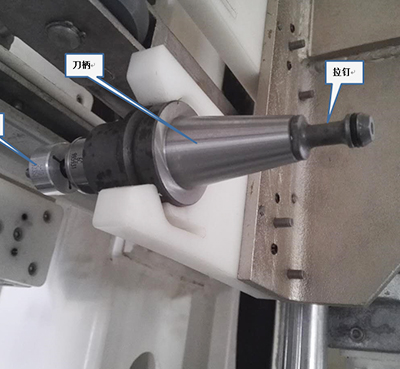

5. GC-LDM is equipped with two electric spindles matched by professional electric spindle manufacturers, with an output power of 7.5kW and a maximum speed of 12000rpm.

|

Product model |

Max.glass size |

Min Glass Size |

Speed of Spindle |

Total Power |

Tool Coner |

Air compression |

|

GC-LDM-2030 GC-LDM-2542 GC-LDM-3060 |

2000*3000mm 2500*4200mm 3000*6000mm |

500×500mm |

0-12000rpm |

22KW |

BT30 |

0.7Mpa |

|

Glass Thickness |

Spindle Power |

Electricity |

Tool Positions |

No,of Axis |

mm Dimension |

|

|

5-19mm |

7.5KW*2 |

3P 380V/50HZ |

8×2

|

5 axis |

9300*2500*3700mm 11700*2500*4200 15300×2500×4700 |

|

|

Main Technique Parameter |

||||||